Table of Contents

- The Dawn of a New Era: The Completion of the First 3D-Printed House in the USA

- Introduction: Standing Amidst Concrete and Innovation

- Historical Context: The Roots of 3D Printing and Construction Revolution

- The Visionaries Behind the Dream: Pioneers of 3D-Printed Homes

- The Technology Unveiled: How 3D Printing Transformed Building Practices

- From Concept to Reality: The Challenges of the 3D-Printed House Project

- Laying the Foundations: Material Science Meets Architectural Ingenuity

- The Printing Process: Watching a House Rise Layer by Layer

- Beyond Speed: The Environmental Promise of 3D-Printed Housing

- Human Stories: Architects, Engineers, and Workers on the Frontline

- Overcoming Skepticism: Public and Industry Responses to the 3D-Printed Home

- The Financial Equation: Cost Efficiency and Economic Impacts

- Regulatory Hurdles: Navigating Building Codes and Legal Frameworks

- The Sociocultural Dimension: What 3D-Printed Housing Means for Communities

- Broader Implications: 3D-Printed Houses and the Future of Affordable Housing

- Global Ripples: How the USA’s Milestone Influenced Worldwide Practices

- Innovation in the Pandemic Age: Accelerating Change amid Crisis

- Lessons Learned: Technical and Social Insights from the Project

- Legacy and Continuity: Next-Generation 3D-Printed Architectures

- Conclusion: A New Blueprint for Humanity’s Shelter

- FAQs: Unpacking the Revolution of 3D-Printed Homes

- External Resource: Further Reading and References

- Internal Link: Visit History Sphere

2. Introduction: Standing Amidst Concrete and Innovation

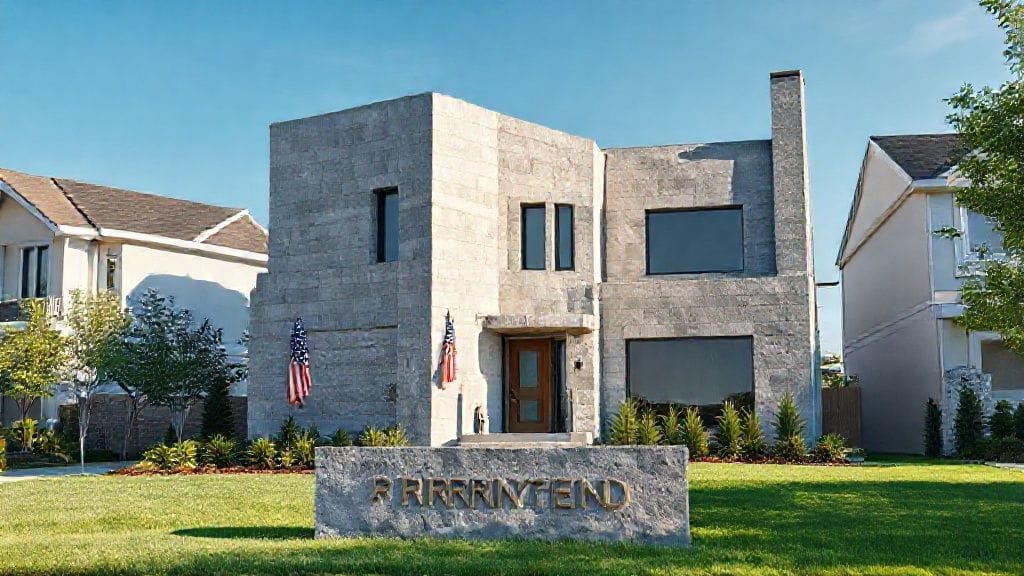

In the heart of a quiet American neighborhood, surrounded by traditional brick houses and sprawling lawns, a singular structure commands attention—its form emerging not from conventional labor but from the rhythmic hum of a robotic arm, extruding layers of concrete with patient precision. This was no ordinary building site. When the first 3D-printed house in the United States was completed in 2021, it was more than just a fresh coat of paint on construction technology; it was a bold proclamation. Here stood a proof of concept that promised to reshape how humans dwell—the formidable intersection of creativity, technology, and social necessity. Concrete flowed, layer by layer, an emblem of future possibilities mixed with earth, innovation, and hope.

The birth of this house was not merely the result of mechanical ingenuity but of decades-long dreams about how to address pressing social issues such as housing affordability, environmental sustainability, and disaster resilience. The 3D-printed house, in its quiet grandeur, marks a historical inflection point—a moment when the future of living spaces was forged with cold precision but warm ambition.

3. Historical Context: The Roots of 3D Printing and Construction Revolution

Though the 3D-printed house completed in 2021 might feel like a sudden breakthrough, this moment rested on the accumulated intellectual and technical groundwork laid over decades. Additive manufacturing, known commonly as 3D printing, had begun as an experimental process in the 1980s, initially aimed at rapid prototyping for small plastic objects. As the technology matured, materials expanded to metals, ceramics, and finally composites robust enough for structural use.

Yet the leap to printing an entire house did not come without visionaries who perceived additive manufacturing’s potential beyond industry or art. For years, researchers and architects toyed with the idea of automating construction—a field notorious for inefficiency, high costs, and environmental impact. The promise was not just speed but creating homes that were customizable, sustainable, and affordable.

The growing housing crisis in the US—marked by price surges even before the pandemic—added urgency. Tens of millions faced homelessness or housing insecurity. Traditional construction could not keep up. The arrival of affordable, fast, and resilient housing was not just futuristic dreaming; it was a potential solution to a real-world emergency.

4. The Visionaries Behind the Dream: Pioneers of 3D-Printed Homes

Behind the whirring machines were visionaries whose stories entwine technology with social responsibility. Companies such as Icon, in partnership with housing nonprofit New Story, spearheaded the American push toward 3D-printed habitable structures. Icon’s CEO, Jason Ballard, a former marine and passionate advocate for affordable housing, envisioned robotic construction as a way to empower communities often overlooked by traditional builders.

Alongside them stood engineers from leading universities—labs where material scientists, programmers, and architects brainstormed the perfect concrete mixture that could flow, set fast, and stand strong against the test of time. This network of innovators blended youthful daring with decades of experience, challenging norms with resolute ambition.

Their goal was not simply to construct a house but to craft a replicable, scalable model that could extend to vulnerable populations globally, from hurricane-ravaged coasts to underdeveloped urban areas.

5. The Technology Unveiled: How 3D Printing Transformed Building Practices

Imagine a colossal printer, the size of a small truck, equipped with an extruder that dispenses a quick-setting concrete mixture guided by highly detailed 3D plans. This printer layers material meticulously, precisely shaping walls, curves, and innovative architectural details without human hands handling bricks or mortar.

Unlike traditional builds that rely on hundreds of workers, days of waiting for foundations to settle, and massive amounts of waste, the 3D printer could build a robust home in mere days. The “printing” process means parts can be designed digitally to optimize strength and thermal regulation, and materials can be tailored to reduce environmental damage.

Moreover, this technology offered a new aesthetic language—organic shapes and complex geometries previously impossible or too expensive to achieve could emerge effortlessly from the printer’s nozzle. Yet behind this wonder were challenges: controlling the drying time, ensuring structural integrity, and integrating electrical and plumbing components seamlessly—all of which required relentless testing.

6. From Concept to Reality: The Challenges of the 3D-Printed House Project

Building the first 3D-printed house was an act of faith as much as engineering. Early skepticism abounded. Could a “printed” structure truly withstand harsh weather conditions, fire hazards, or seismic movement? Would it meet the rigorous building codes of American cities? And critically, could it actually reduce costs or production time without compromising quality?

The project grappled with these questions daily. Trial runs delivered unexpected obstacles: the concrete sometimes cracked prematurely, the scale of the printer created logistical headaches, and integrating traditional systems into this new type of shell tested the engineers’ ingenuity.

Permitting was another thorny issue, as city officials grappled with legislation written for centuries-old technologies. Yet, the team navigated each challenge by embracing transparency, inviting inspection, iterating prototype designs, and building trust one layer at a time.

7. Laying the Foundations: Material Science Meets Architectural Ingenuity

Central to success was the development of specialized concrete blends. Unlike regular cement mixes, the 3D-printable concrete needed to balance flowability with rapid setting time—a tightrope walk that material scientists navigated through chemical admixtures and fiber reinforcement.

These mixtures had to adhere to both structural strength norms and machine specifications—winning international awards for innovation along the way. The mix also minimized environmental impacts, incorporating geopolymer components or recycled aggregates that reduced carbon emissions significantly compared to conventional cement.

Meanwhile, architects designed not only walls but functional niches for insulation, conduits, and windows, effectively embedding those details directly into the print sequence. This holistic approach redefined what a “foundation” could be: not just a base of the house but a living, living part of its entire structural ecosystem.

8. The Printing Process: Watching a House Rise Layer by Layer

Early in 2021, the site became a stage for a spectacle of technology. The 3D printer, mounted on a movable gantry, painstakingly extruded continuous strands of concrete in nearly horizontal layers. Cameras and sensors monitored every inch, adjusting flows in real-time to correct minor deviations.

Within days, the walls reached their full height—some curved, some flat, all resolutely solid. Compared to months of manual labor, the speed was staggering. Workers, now freed from repetitive tasks, focused on quality control, system integrations, and finishing touches.

For onlookers and media, the construction resembled alchemy: a building literally “emerging” from the earth, layer after layer, as if the future was being constructed right before their eyes.

9. Beyond Speed: The Environmental Promise of 3D-Printed Housing

This innovation promised something far deeper than rapid construction: a significant step toward sustainability. Traditional housing production is notoriously wasteful—up to 30% of materials can be wasted—and cement manufacturing is a leading contributor to global CO₂ emissions.

3D printing minimized waste by depositing only the necessary material layer by layer. Moreover, the formulations used could integrate industrial byproducts, reducing ecological footprints. The ability to produce structures with superior insulation also meant lower energy consumption over the building’s lifespan.

The house became a testament to the fact that human creativity could bend the arc of environmental damage, offering a path where progress and ecology could coexist.

10. Human Stories: Architects, Engineers, and Workers on the Frontline

Behind the machines were individuals whose dedication infused this project with soul. Maria, a materials engineer, spoke of the pride in mixing concrete that could "give shelter where it was most needed." John, a site technician, recalled watching the walls rise as “a dream made real.”

Their collaboration spanned continents and disciplines—not unlike a symphony where each expert contributed a distinct note. The project transcended labor; it became an exercise in hope and human ingenuity.

11. Overcoming Skepticism: Public and Industry Responses to the 3D-Printed Home

News of the project traveled fast, meeting both enthusiasm and doubt. Traditional builders worried about job losses, building inspectors questioned code adherence, and homeowners wondered if “printed” meant less safe or less beautiful.

Yet, as houses were tested and certified, perceptions shifted. Pilot housing programs demonstrated comfort, durability, and affordability. Prominent architects issued endorsements, and even some construction unions began exploring ways to upskill workers to new technologies.

Public awareness campaigns stressed how this innovation could complement rather than replace human labor—especially in underserved areas where construction workers were scarce or cost prohibitive.

12. The Financial Equation: Cost Efficiency and Economic Impacts

One of the most tangible promises of 3D-printed homes was cost saving. Labor, which often constitutes 30-40% of a construction budget, could be drastically reduced. Materials were used more efficiently, and construction timelines shortened from months to weeks or even days.

For government programs focused on affordable housing, this represented a paradigm shift. Grants and subsidies could stretch farther, and the initial investment in machinery was offset by scalability and speed.

However, the economic ripple effects were complex. Supply chains, training programs, and building maintenance industries faced recalibration. Still, the potential to rebalance economic access to housing was recognized as a formidable social good.

13. Regulatory Hurdles: Navigating Building Codes and Legal Frameworks

While technology progressed swiftly, laws adapted more slowly. Building codes in the US had traditionally been written for wood, brick, or steel construction. The introduction of a novel material and process raised legal uncertainty.

Teams worked closely with standards bodies to develop testing protocols, safety certifications, and inspection criteria customized for 3D-printed structures. This dialogue laid groundwork not only for the immediate project but for future innovations in construction.

Overcoming regulatory inertia became a story of collaboration, patience, and forward-thinking governance.

14. The Sociocultural Dimension: What 3D-Printed Housing Means for Communities

A house is never just bricks and mortar; it shapes lives, families, and communities. The 3D-printed house project prioritized social inclusion from the start.

Many initial deployments targeted low-income families, disaster survivors, and communities marginalized from traditional home ownership. Beyond providing shelter, the houses offered dignity, stability, and a tangible promise of future opportunity.

Neighborhoods embracing these homes witnessed renewed civic pride and debate on how technology could uplift humanity at its most basic level—where we lay our heads each night.

15. Broader Implications: 3D-Printed Houses and the Future of Affordable Housing

The 3D-printed house was more than a single achievement: it foreshadowed a radical rethinking of affordable housing. By enabling fast, customizable, and sustainable homes, it set a template for public-private partnerships, disaster relief housing projects, and even space colonization concepts.

Imagine entire neighborhoods printed with designs optimized for local climate, needs, and aesthetics—built in weeks, affordable for many, and kind to the planet.

This vision might have once seemed futuristic. Yet today, it is a burgeoning reality.

16. Global Ripples: How the USA’s Milestone Influenced Worldwide Practices

Following the American milestone, countries worldwide accelerated their own projects. From Latin America to Africa and Asia, 3D-printed homes became part of broader efforts to combat housing crises.

International collaborations emerged, sharing materials science data, printer designs, and policy frameworks. The USA’s pioneering achievement acted as a beacon, inspiring innovation and hope across borders.

17. Innovation in the Pandemic Age: Accelerating Change amid Crisis

Ironically, the COVID-19 pandemic intensified the urgency for innovations like 3D-printed housing. Supply chain disruptions and labor shortages exposed fragilities in traditional construction.

The robotic, automated nature of 3D printing helped mitigate virus transmission risks on-site, and rapid construction answered the urgent need for emergency shelters and healthcare facilities.

In this difficult moment, the 3D-printed house emerged as a hopeful symbol of resilience and adaptability.

18. Lessons Learned: Technical and Social Insights from the Project

The project revealed invaluable lessons. Technically, material durability, printer mobility, and integration of utilities require ongoing refinement. Socially, stakeholder engagement and transparent education are key to acceptance.

Investment in workforce development ensures that displaced workers find roles as technicians and supervisors rather than victims of automation.

Ultimately, the journey of the 3D-printed house is ongoing—an evolving narrative of innovation intertwined with human needs.

19. Legacy and Continuity: Next-Generation 3D-Printed Architectures

As of 2024, the blueprint laid by the initial 3D-printed houses has expanded to multifamily dwellings, community centers, and experimental eco-villages. Breakthroughs in printable materials—from bio-based concretes to embedded sensors—point to smart homes printed layer by layer.

This evolution marries technology with ecology and humanity in profound ways, reshaping not only shelter but urban life itself.

20. Conclusion: A New Blueprint for Humanity’s Shelter

The completion of the first 3D-printed house in the USA in 2021 was more than a technological feat; it was a human story of hope born from complexity and collaboration. It summoned dreams of a future where construction is faster, greener, and more inclusive—where a home can be crafted not just by hands but by the promise of progress.

Though challenges remain, this singular house stands as a monument to the power of innovation, reminding us that technology, when aligned with human values, can build a shelter not only against nature’s forces but for humanity’s dignity and dreams.

Conclusion

The journey of the 3D-printed house embodies the spirit of modern human endeavor: a dance between evolving technology, social challenges, and environmental responsibility. While a single house was completed in 2021, it signaled the opening of a vast frontier where homes could be customized, affordable, and sustainable.

More than bricks and mortar, the 3D-printed house represents a narrative of resilience, ingenuity, and the quest for a better future. Its legacy is not only in the structures it builds but in the communities it empowers and the conversations it sparks about what it means to truly inhabit our shared world.

FAQs

Q1: Why is the “3D-printed house” considered a revolutionary development in construction?

A1: Because it drastically reduces build time and material waste while enabling affordable, customizable, and sustainable housing. It also introduces automation that can address labor shortages and improve safety.

Q2: What materials are used in 3D-printed houses, and how do they differ from traditional ones?

A2: They primarily use specially formulated concrete mixes with additives to improve flow and quick setting, sometimes incorporating recycled materials or bio-based components to reduce environmental impact.

Q3: Who were the main companies involved in developing the first 3D-printed house in the USA?

A3: Icon, a construction tech startup, partnered with nonprofit New Story to pioneer the project, blending technology with social impact goals.

Q4: What challenges did the team face during construction?

A4: Major challenges included ensuring the material set correctly, passing building codes, integrating traditional electrical and plumbing systems, and overcoming skepticism from regulators and the public.

Q5: How does 3D-printed housing impact affordable housing efforts?

A5: By reducing labor and material costs and speeding up construction, 3D printing makes it easier to produce affordable homes quickly, potentially reducing homelessness and housing insecurity.

Q6: What is the environmental significance of 3D-printed houses?

A6: They reduce material waste, use greener concrete alternatives, and offer better insulation, all of which contribute to lower carbon footprints and energy consumption.

Q7: How has the completion of the 3D-printed house in 2021 influenced global construction trends?

A7: It inspired a wave of research and pilot projects worldwide, encouraging collaboration between countries and accelerating adoption of additive manufacturing in housing.

Q8: What future developments are expected in 3D-printed architecture?

A8: There will likely be more complex buildings, integration of smart technologies, and continued material innovation leading to even more sustainable and resilient homes.